Multi-beam systems are the key to scaling power, speed and costs

Ultrashort pulsed (USP) laser radiation can process virtually any material at the highest precision. To increase the economic benefit of USP processing, research uses different hardware approaches to address the handing of increased high average laser powers with more than 100 watts, thus, upscaling processing speeds and lower unit costs. One popular method to implement these large laser powers is to split the high-energy radiation into many individual beams. This approach is already being used industrially, particularly for two-dimensional laser material processing or for the generation of periodic patterns such as filters.

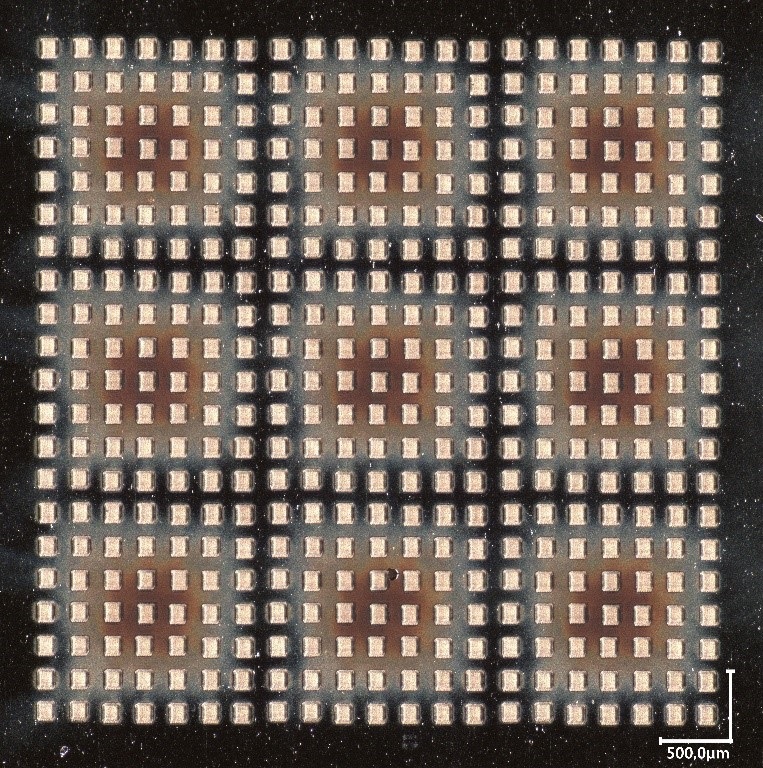

Phase masks are used to generate a parallelized beam patterns with a large number of partial beams from one incident beam. This works dynamically with spatial light modulators (SLM) or statically with diffractive optical elements (DOE) made of glass. SLMs can dynamically change the phase pattern and, thus, also the beam matrix, while static DOEs can withstand higher average powers.

SLMs are particularly suitable for developing manufacturing processes that use USP laser radiation since the beam properties can be easily adapted and tailored. This applies to both the beam profile as well as the arrangement of the individual beams within a pattern. In series production, SLMs are advantageous if beam patterns have to be changed dynamically during the process. If the beam parameters are known and static, DOEs are the better choice due to their insensitivity.

“Joint Application Lab” at Fraunhofer ILT

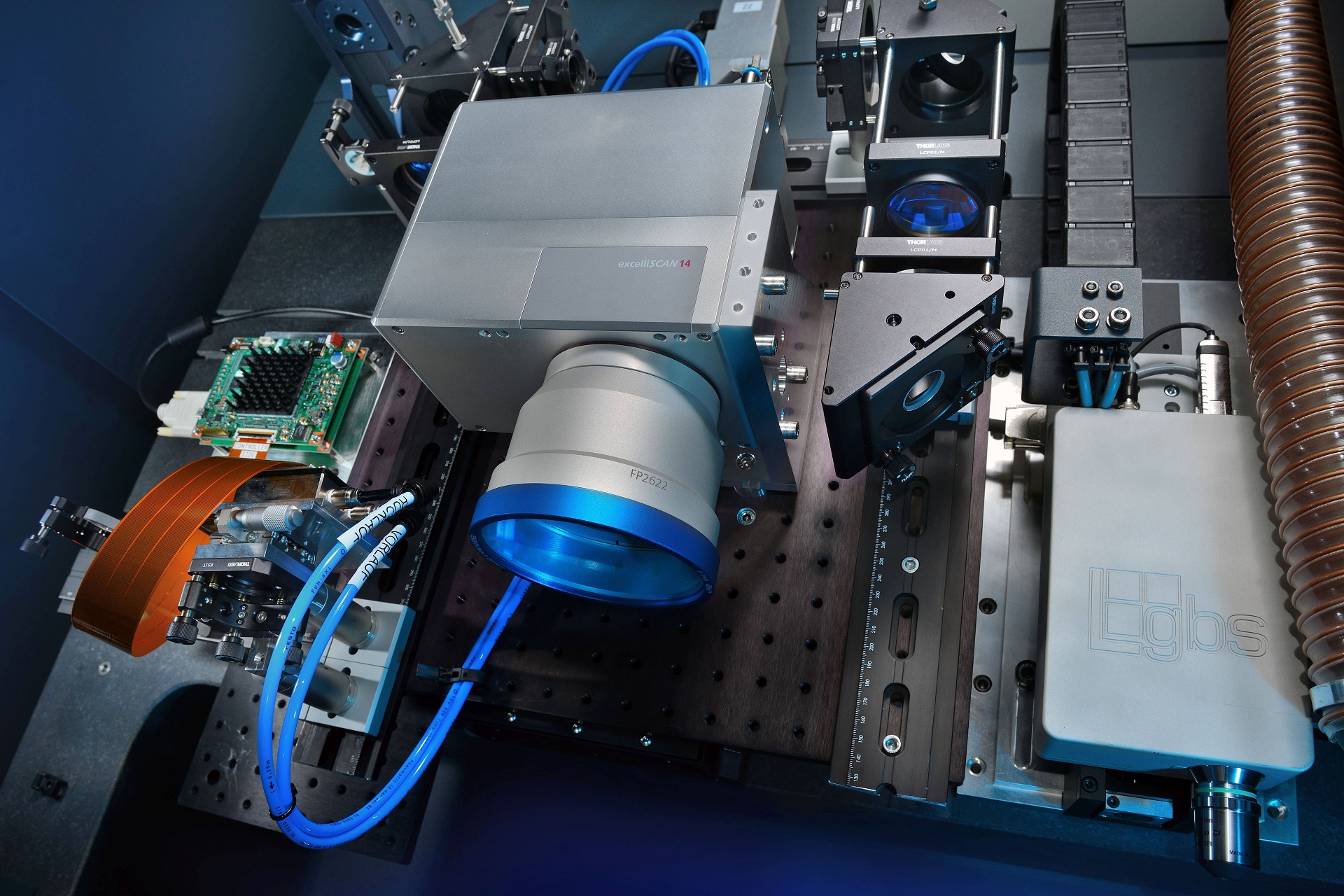

Together with the SLM manufacturer Hamamatsu, a “Joint Application Lab” has been set up at Fraunhofer ILT. There, an industry-ready prototype is ready for the development of manufacturing processes. This includes a scanner-based process head in which Hamamatsu's new high-power SLM is integrated. The head is integrated into a 3-axis machine with a 150 W USP laser.

The new SLM has been optimized for high average power and is currently being introduced to the market. Hamamatsu received funding from the Japanese government to establish the new laboratory under the Cross-ministerial Strategic Innovation Promotion Program (SIP).

SLM enables high power in the application

In Aachen, the system with the new SLM has been in use for various processes and applications since May 2022. The team of Hamamatsu and Fraunhofer ILT has investigated the surface and volume ablation with different beam profiles and focus diameters. The flexible liquid modulator eliminates the need for tool changes.

The heat distribution in the workpiece has become increasingly important when large average laser powers are applied and USP processes are scaled in speed and efficiency. Thanks to the support of the Instruction and Research Department for Nonlinear Dynamics of Laser Manufacturing Processes (NLD) at RWTH Aachen University, Fraunhofer ILT has been able to simulate the processes completely. In this way, the energy distribution and, thus, the heat input within a parallelized beam distribution can be optimized.

In the “Joint Application Lab,” Fraunhofer ILT helps its customers to develop manufacturing processes. In addition, it also uses the know-how and technology it develops in new research projects.

Fraunhofer Cluster of Excellence

Fraunhofer Cluster of Excellence